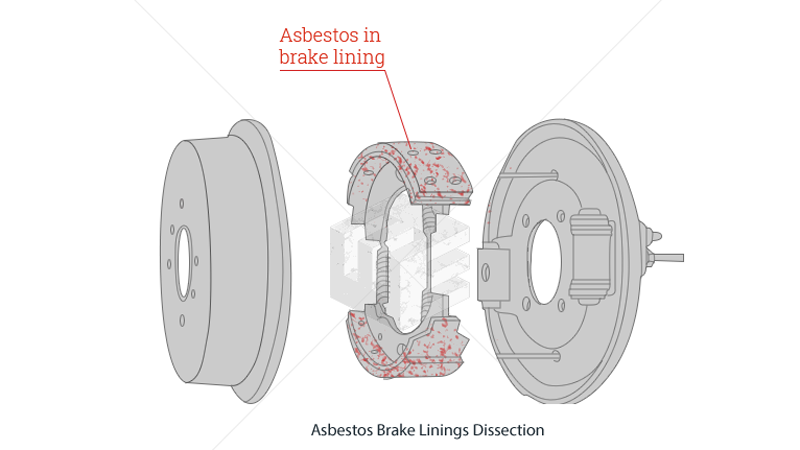

Asbestos brake linings

Before a brake repair job, the accumulated brake dust must be cleaned by the mechanic prior to the old parts being removed. Another case of asbestos exposure may be when installing new brake pads or shoes and the auto-shop worker may grind the surface to speed up the 'breaking in' process, creating dangerous asbestos dust.

Claim Evaluation