Asbestos boilers

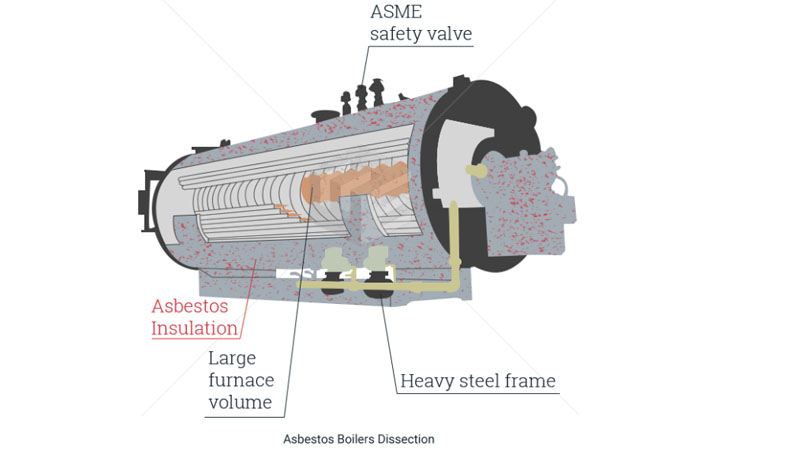

Working around these types of machinery always presented dangerous levels of asbestos exposure. When a boiler required maintenance, you had to pass through its insulation. By cutting and removing it, asbestos dust was created, releasing dangerous particles around you.

Claim Evaluation